Decoding Your VIN: What It Actually Means and How to Read It

Decoding Your VIN: What It Actually Means and How to Read It

TL;DR

- A Vehicle Identification Number (VIN) is a standardized, position-based identifier that encodes a vehicle’s factory configuration, not its usage history.

- Each of the 17 characters has a fixed technical role, governed by international VIN standardization rules adopted after 1981.

- VIN decoding supports regulatory compliance, recall precision, OEM parts compatibility, and fraud detection.

- Public VIN decoders may disagree because Vehicle Descriptor Section (VDS) rules are manufacturer-specific and often proprietary.

- VIN literacy reduces costly errors by revealing when assumptions based on model year or trim name are unreliable.

What a VIN Really Is and What It Is Not

A Vehicle Identification Number (VIN) is a standardized, position-based identifier that encodes manufacturing and configuration data about a vehicle. It is not a database record, a vehicle history report, or a guarantee of condition.

A VIN answers one practical question: what exactly was this vehicle when it left the factory? Registration, recalls, parts catalogs, and insurance records rely on that baseline identity, but they are separate systems that reference the VIN rather than being contained inside it.

What a VIN Is

- A globally standardized 17-character identifier

- A manufacturer-defined encoding system governed by VIN standards and regulatory requirements

- A method to uniquely distinguish one vehicle from every other vehicle produced

What a VIN Is Not

- A vehicle history report that confirms accidents, mileage, or ownership

- A real-time status indicator

- Proof of maintenance quality or current condition

Confusing configuration identity with vehicle history leads to predictable errors, including incorrect parts ordering and unreliable comparisons between vehicles that appear similar on paper. VINs describe factory configuration, while history data lives in external reporting systems.

Quick Comparison: VIN vs Vehicle History Report

- VIN: Factory-defined, fixed, position-based identifier

- Vehicle history report: Third-party aggregated events that change over time

- VIN: Identifies configuration

- Vehicle history report: Describes reported events

Why VINs Exist: Regulation, Safety, and Traceability

VINs exist to make vehicle traceability workable at scale across manufacturers, markets, and regulatory jurisdictions. Without VINs, recalls, safety enforcement, emissions compliance, and theft prevention would rely on inconsistent serial systems and manual verification.

VIN standardization (notably the post-1981 17-character system) supports three operational goals: standardization, accountability, and verification. Those goals are reflected in how VINs connect to registration systems, manufacturer databases, and insurance workflows.

Regulatory Foundation

- VINs support compliance tracking for safety and emissions requirements.

- Regulators use VINs to scope investigations and identify affected production ranges.

- Safety requirements such as Federal Motor Vehicle Safety Standards (FMVSS) rely on precise identification in recall and defect processes.

Safety and Recall Precision

- Recalls require identifying specific model years, plants, and production ranges.

- VIN segments enable targeted campaigns rather than broad, high-cost actions.

- Technical bulletins often reference plant codes and production sequences.

Theft Prevention and Fraud Detection

- VINs are used in registration, insurance, and law enforcement databases.

- A check digit can expose simple VIN alterations and transcription errors.

- Multi-location VIN markings support inspection and verification.

Why Pre-1981 Vehicles Are Different

- Older vehicles may use manufacturer-specific serial formats and varying lengths.

- Decoding reliability is lower without standardized 17-character structure.

- Manual inspection and documentation are often required.

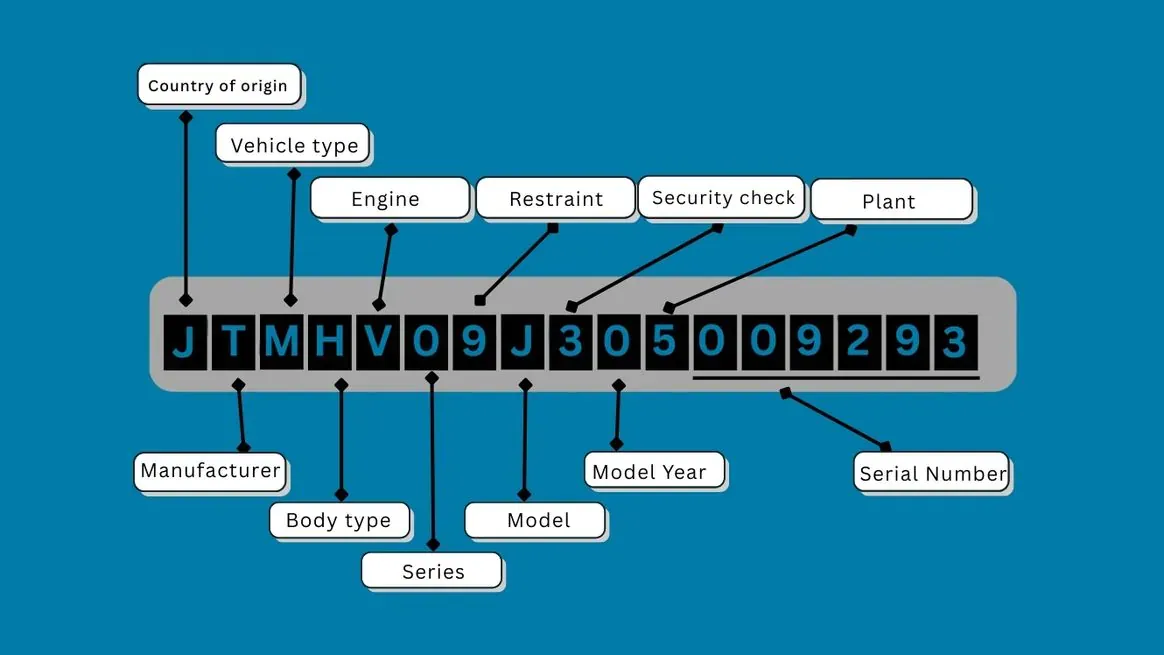

VIN Structure Explained: The 17-Character Framework

A VIN always contains 17 characters, and each character’s meaning depends on its position within the string. The same character can represent different information in different positions, which is why VINs should be treated as structured code rather than a readable phrase.

Seventeen characters provide enough combinations to uniquely identify vehicles while supporting validation methods like the check digit. This structure also enables consistent processing across government systems, insurance platforms, and OEM service tools.

Allowed Characters

- Numbers 0–9

- Letters A–Z, excluding I, O, and Q to reduce confusion with 1 and 0

Positional Breakdown (High-Level)

- 1–3: World Manufacturer Identifier (WMI)

- 4–8: Vehicle Descriptor Section (VDS)

- 9: Check digit

- 10–11: Model year code and assembly plant code

- 12–17: Sequential production number

VINs are deterministic systems that encode information using predefined rules. If a decoder does not have the correct manufacturer mapping, it may return incomplete or conflicting interpretations, especially in the VDS.

World Manufacturer Identifier (WMI): Characters 1–3

The World Manufacturer Identifier (WMI) identifies the manufacturer and the regulatory origin associated with the vehicle. It is not a simple “made in” label and can differ from the vehicle’s final assembly location.

In practice, WMI anchors how compliance responsibility is assigned. It also influences how systems group vehicles by corporate entity, brand, and production category.

Character-by-Character Breakdown

- Character 1: Country or region of origin

- Character 2: Manufacturer or corporate group

- Character 3: Vehicle type or brand division

Why WMI and “Made In” Don’t Always Match

- WMI reflects certification authority and corporate responsibility.

- Final assembly may occur in a different country than the WMI suggests.

- Shared platforms and multi-brand production can result in different WMIs in the same plant.

Quick Comparison: WMI vs Assembly Plant Code

- WMI (1–3): Corporate identity and regulatory origin

- Plant code (11): Physical factory used for final assembly

Vehicle Descriptor Section (VDS): Characters 4–8

The Vehicle Descriptor Section (VDS) defines key configuration attributes such as body style, engine family, drivetrain, and restraint systems. It is the VIN segment most likely to produce conflicting results across public decoders because its encoding is manufacturer-defined.

OEM service tools and an OEM parts catalog typically resolve VDS codes against build logic rather than relying on generalized trim assumptions. That is why VIN-based parts lookup is usually more reliable than year-make-model filters.

What VDS Commonly Encodes

- Engine family or variant group

- Body configuration (doors, cab style)

- Drivetrain type (FWD, RWD, AWD)

- Safety and restraint system generation

Why Public VIN Decoders Disagree

- Partial datasets and incomplete manufacturer mappings

- Generalization across trim lines and mid-year changes

- Different interpretations of configuration codes

Practical Implication

If two vehicles differ in VDS characters, treat them as mechanically distinct until verified. Marketing trim names are not a dependable proxy for configuration when ordering parts or confirming equipment.

The Check Digit (Character 9): VIN Math That Prevents Fraud

The check digit verifies the validity of the VIN string itself. It does not describe the vehicle, but it allows systems to detect errors and simple forms of fraud by confirming the VIN matches a weighted mathematical rule.

If a VIN is altered or mistyped, the check digit may no longer match. This can lead to rejection in registration, insurance, and OEM systems that validate VIN integrity before processing records.

What the Check Digit Does

- Detects transcription errors

- Helps prevent simple VIN forgery

- Flags mismatches consistent with cloned or altered VINs

How It Works (Conceptually)

- Each character is assigned a numeric value.

- Each position is assigned a predefined weight.

- The weighted sum is calculated and reduced using a remainder rule.

- The result determines the check digit (sometimes X represents ten).

Where It Is Used

- Title and registration processing

- Insurance quoting and claims validation

- Recall eligibility checks

- Fraud screening workflows

Model Year and Assembly Plant: Characters 10–11

Character 10 identifies the model year code, and Character 11 identifies the assembly plant code. These two characters are frequently used to scope recalls, technical bulletins, and compatibility decisions.

Model year is a regulatory designation and does not always match the calendar build date. The assembly plant code can matter because suppliers, routing, and mid-year running changes can vary by plant even within the same model year.

Model Year Code

- Uses an alphanumeric cycle that repeats over time.

- Requires context (and sometimes documentation) to resolve across decades.

- Reflects model year designation, not necessarily build month or sale date.

Assembly Plant Code

- Identifies the factory responsible for final assembly.

- Supports recall scoping and technical service documentation.

- Can correlate with supplier and component variations.

Quick Comparison: Model Year vs Build Date

- Model year: Encoded in VIN and used for regulatory grouping

- Build date: Often found on the vehicle certification label and used for service context

Sequential Production Number: Characters 12–17

Characters 12–17 form the vehicle’s sequential production number, uniquely distinguishing it from other vehicles with the same WMI, VDS, and year/plant codes. This sequence is typically managed within plant or production constraints, not as a global counter across all factories.

Production sequences can be used in OEM documentation to define cutoffs for running changes. They do not reliably indicate rarity, total production volume, or quality ranking.

What It Represents

- A unique identifier within a manufacturer’s production logic

- A reference point for production cutoffs and running changes

- A differentiator between otherwise identical configurations

What It Does Not Represent

- Total production volume across all plants

- Collectibility or rarity on its own

- A quality tier ranking

How VIN Decoding Is Used in the Real World

VIN decoding is operationally important because it influences parts selection, recall eligibility, registration workflows, and insurance validation. Professional systems use the VIN to establish configuration before deciding which rules, procedures, or components apply.

Parts Identification

- VIN-based filters reduce mismatch risk compared to year-make-model selection.

- An OEM parts catalog may encode running changes using VIN ranges.

- Electronics and safety components often require VIN-specific matching.

Insurance and Claims

- VINs validate declared vehicle specifications and identity consistency.

- Check-digit validation can flag incorrect or altered VIN strings.

- Configuration mismatches can delay underwriting and claims resolution.

Vehicle History Reports

- A vehicle history report aggregates events tied to a VIN.

- It does not necessarily confirm factory-installed options or configuration accuracy.

- History data should be evaluated separately from VIN configuration decoding.

Common VIN Mistakes That Cost Owners Money

Most VIN-related mistakes are caused by treating trim names and model years as proxies for configuration. VIN segments exist because these proxies fail when manufacturers introduce mid-year changes, supplier updates, or plant-specific variations.

High-Cost Missteps

- Ordering parts based on trim name rather than VIN-resolved configuration

- Assuming the same model year implies identical mechanical setup

- Ignoring assembly plant and production sequence differences

- Using partial VINs when full VIN verification is required

How Professionals Reduce Error

- Decode the full 17-character VIN and validate check-digit integrity when applicable.

- Cross-check against OEM documentation and an OEM parts catalog.

- Treat VDS differences as meaningful until verified.

VIN Decoding FAQ

How do I decode my VIN without paying for a report?

You can decode a VIN by understanding positional structure and manufacturer rules. Public VIN decoders can provide baseline results, but configuration accuracy improves when you cross-check WMI, VDS, and model year codes against OEM references.

Why do different VIN decoders show different engine information?

Differences occur because VDS decoding is manufacturer-defined and some tools rely on incomplete mappings. If the tool cannot resolve a VDS code, it may infer a common configuration rather than confirm the exact variant.

Can a VIN tell me my exact trim level?

Sometimes, but not reliably. VINs prioritize configuration and compliance encoding, while trim names often represent bundled options that may not map cleanly to a unique VIN rule. Build sheets and OEM option codes may be required for full trim resolution.

Why does my VIN show one year but my title shows another?

VIN character 10 encodes model year designation, which can differ from calendar build date or first registration year. Titles may reflect sale, registration, or administrative timing rather than model year encoding.

Is my VIN enough to order the correct replacement parts?

It can be, if the system respects VIN specificity. VIN-resolved OEM catalog lookups generally reduce mismatch risk compared to year-make-model selection, especially for electronics, safety components, and mid-year running changes.

Unique Insight: Why VIN Literacy Beats VIN Lookup

Many VIN-related errors are caused by overconfidence in generalized decoding outputs rather than by incorrect VINs. The VIN is precise, but a decoder without the correct manufacturer mapping may return incomplete interpretations, especially in the VDS.

Micro Case Study: Same Vehicle Label, Different Part

Two vehicles can share the same model year, model name, and trim badge while differing in VDS codes, assembly plant codes, or production sequences. Those differences can map to running changes that affect component routing or part revisions, which can lead to incorrect orders when lookup relies on trim labels rather than VIN resolution.

Why This Happens

- Mid-year running changes are common and may not change the trim name.

- Plant-level supplier variations can affect component fitment or routing.

- OEM documentation often scopes procedures by VIN ranges and production cutoffs.

Practical Outcome

VIN literacy helps identify when configuration assumptions are likely to fail. It improves accuracy by prompting verification through OEM references, particularly for safety and electronics components where configuration differences matter.