How Modern Cars Reduce Cabin Noise (and Why Some Still Fail)

How Modern Cars Reduce Cabin Noise (and Why Some Still Fail)

Drivers care about quiet. The way a car sounds inside shapes comfort, fatigue, and how safe you feel at speed. If you want to understand how modern cars reduce cabin noise, you need to look at materials, aerodynamics, tires, powertrains, and digital tricks designed to block, absorb, or cancel sound.

Modern cars reduce cabin noise through a mix of passive materials and active technologies. Automakers add acoustic insulation, laminated glass, tight seals, tuned engine and exhaust parts, low noise tires, and smoother aerodynamics. At the same time, microphone arrays and digital signal processing push active noise cancellation through the speakers to cut steady droning sounds at speed.

The stakes: why cabin noise matters for comfort, fatigue, and safety

Cabin noise does not just ruin a song or a conversation. It raises stress, quickens fatigue, and chips away at situational awareness during long stints behind the wheel. Prolonged exposure to harsh sound is linked to headaches and elevated blood pressure. That carries over to driving performance, especially when a highway trip turns into hours of steady hum and hiss.

Noise sources stack fast. Tires roll over the surface and pump air in the tread grooves. Wind flows around mirrors and pillars. Engines and motors send vibrations through mounts. Any loose panel or poorly fitted trim rattles. If door and window seals leak, noise gets a shortcut into the cabin. The result is a cluttered soundscape that forces your brain to filter constantly, which is tiring and distracting.

Automakers treat noise, vibration, and harshness as a core quality signal. Honda ties NVH to perceived value. Mazda modified strut dampers and interior fabrics to calm low frequency rumble. Rolls Royce packed its Ghost with heavy layers of insulation to shape a signature hush. This shows how far brands will go to create a quiet interior and why cabin sound is part of how a car is judged.

- Comfort. Lower noise levels reduce stress and make daily commutes feel calmer.

- Fatigue. Less droning and hiss reduces cognitive load during long trips.

- Safety. Quieter cabins make it easier to hear sirens, horns, and odd mechanical sounds that signal a problem.

- Value. Many buyers treat cabin hush as a luxury cue, which boosts a model’s reputation and resale.

How modern cars reduce cabin noise: core technologies

Automakers attack noise with a layered strategy. They treat the structure with insulation. They tune engines and mounts to cut vibration. They smooth airflow outside so wind does not roar. They pick tires that roll quietly. Then they add digital cancellation to trim the last bit of droning. That stack is how modern cars reduce cabin noise today.

Passive noise control vs. active systems

Passive control uses mass, damping, and absorption. Materials add blockage and soak up sound energy. Seals close gaps. Laminated glass acts like a solid barrier. Design details shift resonance and route sound through less sensitive paths. All of this happens without electronics. Passive measures aim at broad frequency ranges and work day one without calibration.

Active control uses microphones, sensors, and processors. It listens for steady, repeatable noise signatures. It plays anti noise through speakers to cancel those low frequency sounds inside the cabin. Systems target the bands where ANC is most effective, which tends to be the rumble and droning range rather than sharp impacts. Bose and others have shown road noise cancellation tuned to EVs where the engine is silent but tires and wind are more exposed.

- Passive. Insulation, damping sheets, foams, glass, seals. Always on. No power needed.

- Active. Microphones, DSP, speakers. Most effective on steady low frequency content.

- Best practice. Use passive to set the baseline and active to trim persistent droning at speed.

The source–path–receiver approach to NVH

Engineers map noise as source, path, and receiver. If you identify the source, you can treat the path or block the receiver to hit the problem where it matters. This framework keeps fixes targeted instead of piling weight everywhere.

| Source | Path | Receiver | Common fix |

|---|---|---|---|

| Tire road interaction | Wheel wells, floorpan, body panels | Cabin surfaces and ears | Damping mats on floor, foam liners in wells, mass barrier layers |

| Wind over mirrors and pillars | A pillar, door frame, seals | Cabin leak paths | Smoother mirror shapes, better seals, laminated glass |

| Engine or motor mounts | Subframe, firewall, floor | Seat rails, dash | Tuned mounts, firewall insulation, cross member damping |

| Panel rattles | Trim clips, cupholder areas | Local buzz near occupants | Closed cell foam decouplers and better fasteners |

Materials and structure: body engineering that blocks and absorbs sound

The body in white is a sound instrument. Steel, aluminum, composites, and glass panels ring and transmit energy unless you tame them. Modern cars pack light foams for high frequency absorption, viscoelastic sheets for structure damping, and dense barrier layers to block airborne sound. Glazing and seals add to that baseline.

Lightweight acoustic foams made from polyurethane, polypropylene, melamine, and expanded polypropylene show up inside pillars, floors, roofs, and door cavities. These foams absorb sound without adding much mass and can be shaped and injected into tight spaces.

Brands build sustainability into these materials through recycled content or biodegradable plastics, with some lines designed for circular recovery at the end of vehicle life.

Traditional bitumen and rubber mats still see use in lower frequency control. They add weight and damping to metal panels that otherwise ring when excited by road inputs. Many automakers limit heavy mats because every pound hurts efficiency. The trend pushes toward lighter solutions that still deliver damping on key panels where structural noise dominates.

Acoustic insulation, foams, and damping sheets

Each material does a job. Absorbers soak up high frequency energy in cavities and reduce reverberation. Damping sheets knock down panel vibration and resonance peaks so drumming does not reach the cabin. Barrier layers block airborne noise that sneaks through gaps and thin zones.

- Absorption. Pillar fills, roof headliner insulation, dash pads. Good for hiss and interior echo shaping.

- Damping. Butyl or viscoelastic sheets on floors, doors, trunk. Cuts panel ring and buzz from road inputs.

- Barrier. Dense mass layers under carpet and firewall. Blocks airborne tire and wind noise paths.

Suppliers sell combinations that add damping and a decoupling foam in one sheet. Installers often shoot for partial coverage on large metal panels. A checkerboard pattern can deliver much of the gain without going to full coverage, while high value zones like the cabin side of the firewall and floor produce outsized results.

Laminated acoustic glass and sealing

Laminated acoustic glass stacks layers to make a thicker barrier. Many luxury cars fit laminated windshields and front side windows to add a few decibels of reduction. Some brands claim around three to five decibels from a laminated windshield, which is a very audible change in the front row.

Seals around doors and windows matter more than most people think. If a high speed whistle or whoosh shows up, check the weather stripping. Tight seals reduce wind roar and stop water intrusion. Brands tuck wiper arms under the hood, smooth the trim, and adjust seal profiles to cut leak paths that carry noise into the cabin.

As cost moves down, acoustic glass spreads to mid price models, while entry models rely on better seals and insulation to get acceptable results. This shows how modern cars reduce cabin noise through both premium glazing and careful sealing across the lineup.

Powertrain and drivetrain noise control in ICE, hybrid, and EV

Powertrains set a big slice of the cabin sound profile. Combustion engines need tuned mounts, isolation between the engine bay and cabin, and exhaust routing that hits the right note. Hybrids add mode shifts and engine starts you need to mask. EVs trade engine rumble for motor whine, reduction gear meshing, and inverter switching tones that live in a different frequency band.

Combustion engines, mounts, and exhaust tuning

ICE vehicles push low and mid frequency noise during acceleration. Tuned engine mounts filter vibration that would otherwise run into the subframe and floor. Firewalls get dense barrier mats on the cabin side with absorbers in the engine bay. Exhausts use resonators and mufflers to trim booming and shape a brand voice without drone at highway speeds.

Automakers reinforce weak panels near the spare wheel pan and trunk to avoid reverberation. Mazda strengthened parts near the spare to keep unwanted resonance from traveling into the cabin. This shows how sometimes a single thin panel can be the path that turns a mild noise into an annoying tone.

- Tuned mounts to match dominant engine orders and cut through paths.

- Firewall barrier layers and absorbers on both sides.

- Mufflers and resonators aimed at drone control without choking flow.

E-motor whine, reduction gears, and inverter tones

EVs remove the engine note. That makes road and wind noise more obvious. It also exposes high frequency tones from motors and power electronics. Reduction gears mesh, which can sing if tolerances or lubrication are off. Inverters switch power at high frequency and can add a faint buzz. Engineers target these sounds with tuned mounts, case damping, and filters in the control strategy while the rest of the car gets more passive measures to block tire and wind inputs.

Active road noise control stands out in EVs because the base cabin is quiet. Bose and other audio suppliers built systems that listen for road induced vibration through accelerometers and microphones and then cancel that content through the speakers. EV cabins benefit because there is little engine content to mask road hum.

Brands experiment with sound design. Some add artificial cues at low speed so pedestrians hear a presence. Others pump a restrained engine like tone into the cabin to give feedback about acceleration. These are styling choices, not true ANC. True ANC aims to reduce noise, not add it.

Tires, road, and suspension: the dominant noise at highway speeds

Tire and road noise often dominate once you settle at highway speed. The rolling interaction pumps air in the tread, excites the carcass, and shakes the body. The surface texture matters. Coarse asphalt hisses. Fresh concrete can sing. Weather and temperature shift rubber behavior. All of that creates the background noise that many people live with every day.

Tuning tire compound, tread design, and wheel size helps. Narrower tires and smaller wheels tend to be quieter. Stickier compounds and aggressive tread can hum. Suspension bushings and isolators mute the paths that carry those vibrations into the cabin. Wheel well liners and underbody treatments add another layer of defense.

Tire compounds, foam-lined designs, and tread patterns

Lower noise tires exist. Some fit foam liners inside the tire to absorb cavity resonance. Pirelli and others use polyurethane foam to cut transmitted noise. Tread patterns aim to break up harmonic content and reduce pumping effects at speed. Softer compounds often sound quieter yet trade wear and efficiency. Results vary based on vehicle platform and local roads.

- Foam liners reduce cavity resonance in the tire and lower cabin droning.

- Quieter tread patterns and compounds for daily highway work.

- Rotate and align on schedule. Poor alignment grows noise and wear.

If you plan a tire swap for noise only, wait until your current set is worn. Tests show mixed outcomes. Some drivers hear a clear drop. Others hear little change. The platform and wheel well treatments set a lot of the baseline, which is why aftermarket tire changes are not a sure noise fix.

Wheel wells, liners, and underbody treatments

Wheel wells are a noise gateway. The path from tire to well to floorpan is short. Automakers add felt like liners and sometimes spray on coatings to damp vibration and absorb airborne content. Aftermarket liquid deadeners can be applied behind liners to cut ringing metal and lower road noise paths.

Underbody panels help aerodynamics and noise. Smoother airflow under the car reduces turbulence around the wells. That cuts wind related hiss and can change how road noise couples into the body. Many brands fit plastic or fiber panels for both reasons.

Owners who treat the wells and add mass barrier inside on the cabin side often report clear gains. Cover the floor from the firewall back. Hit the tops of the wheel wells where airborne content couples. Seal any gaps in barrier layers so you do not leave back doors for sound.

Road surface, climate, and accessory effects

Road texture drives the character of the noise. Rural chip seal and coarse asphalt hiss more than smooth fresh asphalt. Cold weather hardens rubber, which raises rolling noise. Hot weather softens it, which lowers noise and changes tread behavior.

Accessories matter. Roof racks add whistling. Mud tires roar. Low profile performance tires hum. Boxy trucks and vans face more wind drag and wind noise at speed. That is why many trucks struggle with wind noise and require attention to seals and mirrors to keep things in check.

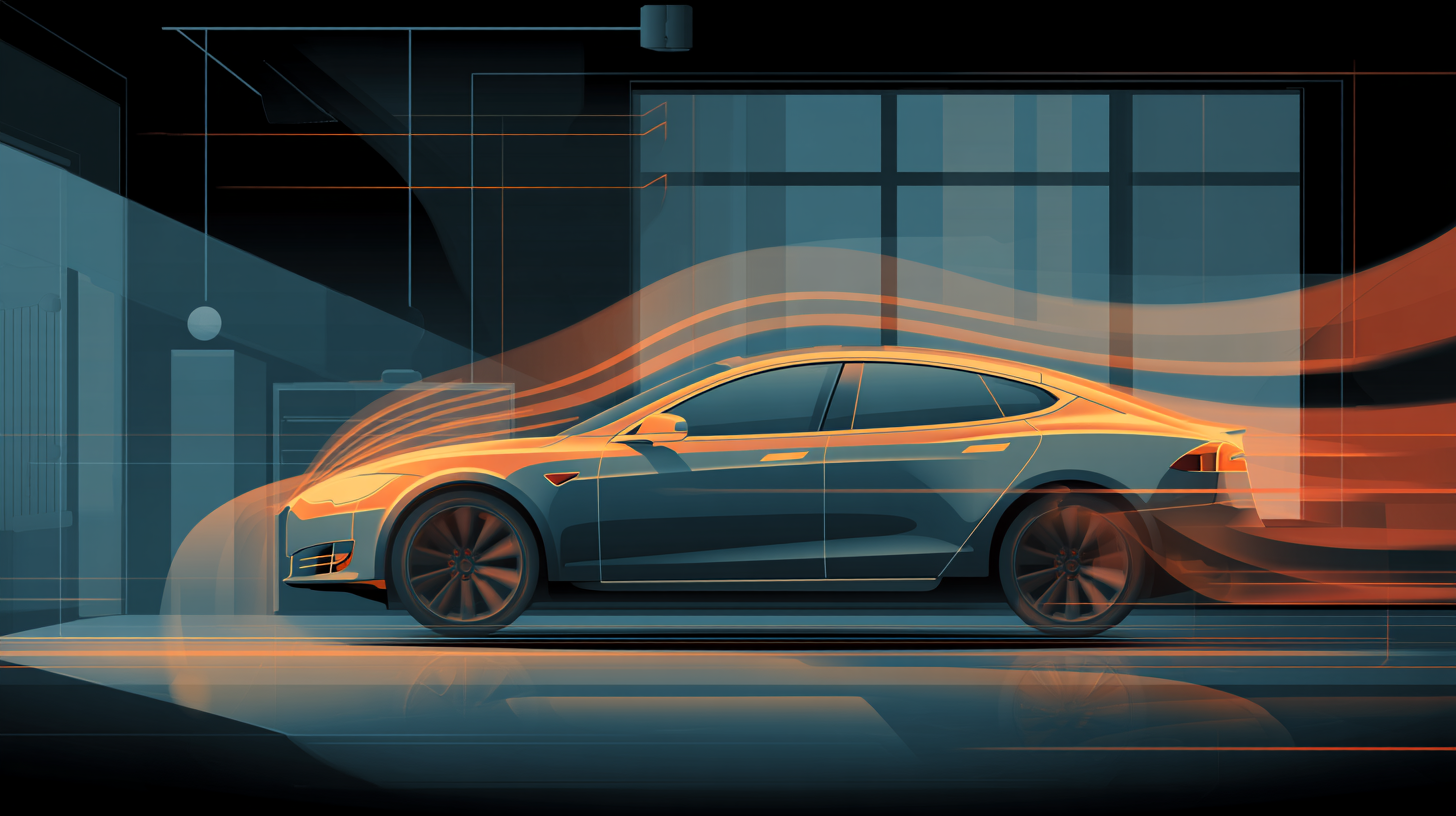

Aerodynamics and exterior sealing that cut wind roar

Wind noise goes up with speed. The shape of mirrors, pillars, and door frames sets the flow. Pop out handles that sit flush with the body cut a source of turbulence. Camera mirrors shrink the protrusion. Shark fin antennas replace old mast designs to avoid a whip sound. Better underbody panels smooth the flow that feeds the edges of the body.

Brands test shapes in wind tunnels and add small lips and creases that steer air into quieter paths. The coefficient of drag matters for fuel, but it also matters for noise. Low drag designs tend to sound calmer at speed because the air has fewer places to separate and

Mirrors, A-pillars, and panel gaps

Mirrors and pillars are wind sound hotspots. Designers shrink mirror housings, change edge radii, and add small channels to route flow quietly. A pillars get fairing treatments. Panel gaps tighten. Better alignment cuts little whistles that appear when air sneaks through seams at speed.

Flush door handles remove a small source of turbulence at the body side. Audi and Tesla have shown camera mirror systems that reduce protrusion and tidy airflow though regulations and driver preferences shape adoption. Even detail parts like antennas get reshaped to avoid whoosh at highway speeds.

These small changes show how modern cars reduce cabin noise by design details that compound. One less whistle here and one less roar there adds up.

Door, window, and roof sealing systems

Seals work best when they are fresh and aligned. Replacing weather stripping around doors and windows often fixes wind noise or water leaks. Roofs and sunroofs need careful sealing. If the roof skin flexes, adding headliner insulation helps. Owners who treated roof panels reported less rain drumming and reduced wind hiss above the front row seats.

Manufacturers tuck wipers under the hood and add fabric to bare metal in the cabin to cut reflection and hiss. Mazda used new headliner material and tucked wiper arms to reduce low frequency noise by a noticeable amount. This shows how sealing and small design choices connect to the final sound.

Digital quiet: active noise cancellation and sound design

Digital quiet starts by listening. Microphones pick up cabin sound. Accelerometers measure body vibration that correlates with road inputs. DSP builds an anti noise signal. Speakers push that signal into the cabin. Done well, the steady hum and low frequency drone fades without adding artifacts.

Active noise systems work best in EVs because engine noise does not step on the cancellation. In ICE vehicles, ANC targets the steady parts of the sound from tires and exhaust that sit in a predictable band. The tech cannot cancel sudden sharp events or voices from other cars. It is built for steady content where phase and timing match well.

Microphone arrays, DSP, and speaker placement

Microphone arrays sit where people sit. They capture cabin sound and feed the DSP. Accelerometers capture road induced vibration. Algorithms map the content to the car and generate anti noise. Speaker placement matters because the cancel field must reach ears in the right phase. Audio suppliers tie the system into the cabin layout to get even results.

- Microphones near headliners and pillars for cabin pickup.

- Accelerometers at mounts and body points to sense vibration.

- DSP tuned to the model and trim with profiles stored in the audio system.

- Speakers used for both music and ANC. Volume and content managed so they do not fight.

As systems evolve, some use machine learning to predict noise changes based on speed and surface and adjust faster. The trend points to more adaptive behavior in future models.

Engine sound enhancement versus true ANC

Engine sound enhancement plays a file or synthesized tone through the speakers to add presence. This is not noise cancellation. It is sound design. Brands use it in performance models to give feedback at low revs or in quiet EVs to add character so drivers feel connected. True ANC reduces noise. Sound enhancement adds it.

Some drivers prefer a natural cabin profile. Others enjoy a tuned sound that reflects acceleration. Test during a drive and decide whether you like the tone or prefer purity.

Testing and metrics: how automakers measure and tune NVH

Automakers chase numbers and signatures. They measure sound pressure and characterize frequency content with weighting curves that better reflect how people hear. They use cameras and simulators to find where noise originates and how it travels. Then they tune materials and shapes to hit targets. This process blends physics and design.

During development, teams drive on known surfaces, run wind tunnel tests, and put cars on multi axis shakers to simulate miles in hours. Acoustic cameras point to hot spots where air or structure emits. Results feed into changes in seals, mounts, and panel thickness. Strain on budget and weight forces trade offs, which is why not every model reaches a luxury level hush.

| Metric | What it means |

|---|---|

| dBA | Sound level with A weighting that emphasizes human hearing range |

| Frequency bands | Breakdown of sound energy by frequency |

| Roughness | Perception of modulation and fluctuation |

| Order tracking | Engine or motor order based signatures |

Tools include acoustic cameras to visualize noise sources, road simulators to apply repeatable inputs, and shakers to excite structure. These help engineers choose whether to add damping, change a shape, or apply ANC.

Why some modern cars still fail at cabin quiet

Not all modern cars sound calm. Some still buzz, drone, or hiss more than buyers expect. Reasons include budget choices, heavier materials that hurt efficiency, and platform decisions that prioritize other goals. Tire choices and supplier variability add noise. Assembly quality and sealing errors create leaks that undo good design.

Cost, weight, and platform trade-offs

Quiet costs money and pounds. Luxury sedans accept heavy mass layers and extensive glass. Entry models cut insulation to hit price and efficiency. Sports cars avoid mass to keep response and speed. Trucks carry larger frontal area and boxy shapes that fight wind noise. These trade offs explain why a compact car will rarely match a flagship in hush.

Engineers pick their battles. They treat the floor and firewall rather than the whole interior. They add a small resonator to avoid exhaust drone but not a big heavy muffler. They soften mirror edges and accept some wind sound to keep style. This is a practical balance.

Tire fitments, supplier variability, and build quality

Tire fitments swing noise. All terrain patterns hum. Performance compounds roar on coarse surfaces. Supplier shifts change foam density in liners or tweak seal geometry. A small trim clip position difference can turn a quiet interior into a rattle under specific conditions. This is why some identical models feel quieter than others on the lot.

Build quality affects seals. If doors are not flush, wind finds a path. Weather stripping that is pinched or damaged becomes a whistle. Dealers can often fix these issues under warranty with alignment and seal replacement. Owners should check this before adding aftermarket materials.

How to reduce cabin noise in car: practical fixes and upgrades

If you are hearing more than you want, you can try a few practical steps. Start with diagnosis. Listen at different speeds on different surfaces. Note whether wind or road dominates. Ask a passenger to listen from the rear. Then plan upgrades based on paths and the value zones that deliver the biggest gains.

Quick wins owners can do today

- Inspect and replace worn door and window seals. Many wind noises come from leaks.

- Check door alignment and latch engagement. Misalignment creates whistle at speed.

- Remove roof racks when not needed. They add wind hiss.

- Rotate and align tires. Poor alignment adds noise and wear.

- Lower music volume to listen for rattles. Find and decouple plastic panel buzz with closed cell foam.

Sound-deadening materials and installation zones

Owners who install damping and barrier layers can cut road noise. Treat the floor from the cabin side of the firewall back. Cover the tops of the wheel wells inside the cabin. Apply damping sheets on large metal panels under the carpet and inside doors. Then add a mass barrier layer over the floor to block remaining airborne noise.

| Zone | Material type | Goal |

|---|---|---|

| Cabin floor | Viscoelastic damping plus mass barrier | Reduce vibrational ring and block airborne road noise |

| Doors | Damping sheets and decoupling foam | Stop panel buzz and cut exterior bleed |

| Wheel wells | Liquid deadener behind liners | Kill ringing in hard to reach areas |

| Roof | Headliner insulation and damping | Lower rain drumming and wind hiss |

Look for strong adhesion, clean surfaces, and sealed barrier layers. Air pockets reduce performance. A roller helps set sheets well and avoid bubbles. Partial coverage yields value, while full coverage maximizes results if weight is acceptable.

When to consult a dealer under warranty

If your car is new and wind or water leaks appear, visit the dealer. Ask for a seal inspection and door alignment checks. If a specific rattle repeats, ask a technician to road test and locate the source. Many noise problems are fixable under warranty. It is better to correct the cause than to add layers that hide symptoms for a while.

- Document the conditions. Speed, surface, temperature. This helps diagnosis.

- Check seals visually and by feel. Look for gaps or crushed sections.

- Ask for a door fit check. Flush surfaces reduce whistles.

- Request a trim inspection. Loose clips and panels are common sources.

- Confirm fixes on the same route used to record the noise. Verify the outcome.

Buying guide: how to test-drive and shop for a quiet car

Shopping for a quiet car starts with the right test drive. Do not limit yourself to a short loop at low speed. Pick routes that include rough asphalt, concrete, and highway stretches. Drive with the audio off. Listen at steady speeds and during gentle acceleration. Compare models back to back on the same route to avoid memory bias.

Test routes, listening tips, and comparison methods

- Plan two routes. One local with mixed surfaces and one highway loop that hits 65 to 75 miles per hour.

- Listen for wind around mirrors and pillars. Note any whistles or whoosh as speed rises.

- Feel for floor vibration. Road droning reveals itself as a steady hum that gets tiring fast.

- Sit in the rear seats. Some cars are quieter up front because of glass and seals. The rear can tell a different story.

- Compare trims with acoustic glass. Laminated front glass changes the sound in the front row.

Ask about tires fitted to the trim. Performance packages often include noisier tires. Trucks and SUVs at base levels may have less insulation. Compact cars tend to cut soundproofing to hit price targets, so adjust expectations or plan upgrades.

Features and options worth paying for

- Laminated acoustic glass on windshield and front side windows for a noticeable drop in front cabin noise.

- Upgraded insulation packages and sound damping mats included in higher trims.

- Active road noise cancellation if you do a lot of highway miles, especially in an EV.

- Smaller wheels with higher sidewall tires for calmer ride and lower noise.

- Mirrors and handles with low protrusion designs. Ask your salesperson about aerodynamic detail changes.

Conclusion: key takeaways and next steps

Cabin quiet is a system. The best results come from stacking smart body materials, tuned powertrain isolation, quiet tires, clean aerodynamics, and active cancellation. When you understand how modern cars reduce cabin noise, you can spot the strong models on a test drive and plan upgrades that actually help. Start with seals and alignment. Treat floors and wheel wells next. Consider acoustic glass and ANC where available. Then keep tires and alignment in shape so the baseline stays calm.

If your current car is louder than you like, build a simple plan. Diagnose the dominant noise. Fix leaks under warranty. Add damping and barrier layers to the right zones. If you are shopping, map routes that reveal wind and road character and test trims with acoustic glass or ANC. Small choices add up. This is how to reduce cabin noise in car without wasting time or money.

Final thought. Modern tech will keep pushing quieter cabins through smarter materials and better ANC. The next step for you is simple. Pick one change and test. You will learn fast and hear the results. That is how modern cars reduce cabin noise and how owners can tune it at home.

About World Parts Direct

World Parts Direct is your go-to source for genuine OEM parts for GM and MOPAR vehicles. We make it easy to order factory-original parts online — shipped fast, accurately, and backed by real human support.

Every item we sell comes brand new in the manufacturer’s original packaging. Whether you’re handling routine maintenance, collision repair, or a full restoration, our parts professionals provide VIN-verified fitment support to ensure you get exactly what you need.

Serving drivers and repair shops worldwide, we proudly support brands like Chevrolet, GMC, Cadillac, Buick, Dodge, Chrysler, Jeep, and Ram. Shop confidently at WorldPartsDirect.com.